Home News/Events Contact Us Select Your Language

Induction Cap Sealing

ABOUT LEPEL THE PROCESS BENEFITS INDUSTRIES PRODUCTS CAP LINER GUIDE SEALING PROBLEMS

The Induction Cap Sealing Process

Induction cap sealing is a non-contact process by which a foil disk or

“seal” is bonded to a container. Developed more than 35 years ago, induction sealing was originally intended to prevent leakage of chemicals from plastic bottle caps. Today, this unique process can be used with most any style container and closure for sealing foods, drugs, beverages, solvents and chemicals.

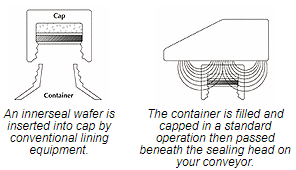

First, the caps are supplied with an aluminum foil induction innerseal, ready to load into the capper. The container is then filled and capped by the existing process, using the caps that are pre-lined with the induction innerseal.

The capped container is then transferred down the conveyor line and passes underneath a Lepel induction sealing head at line speeds up to 300 feet per minute. The electromagnetic field generated by the sealing head penetrates the cap and the aluminum foil layer as the container passes underneath. As the field penetrates the foil, it induces an electrical current flow that quickly generates heat (temperatures of 185°-350°F), which melts the liner’s heat seal film. To prevent liner damage, the sealing head is designed to inductively heat the foil layer of the innerseal structure evenly.

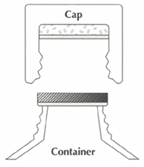

After leaving the induction field, the foil cools and the heat seal film bonds to the container, leaving a hermetically sealed container. When the cap is removed, the aluminum foil remains bonded to the lip of the container. This inductively bonded seal will eliminate product leakage, prevent tampering, lengthen shelf life and enhance customer confidence.