Home News/Events Contact Us Select Your Language

Induction Cap Sealing

ABOUT LEPEL THE PROCESS BENEFITS INDUSTRIES PRODUCTS CAP LINER GUIDE SEALING PROBLEMS

Cap Liner Guide

Choosing the right materials and structure for your innerseal is necessary to ensure the right amount of protection for your product. Lepel can assist you in choosing the materials and construction appropriate to your application.

jomashop replica watchCap Liner Providers

Lepel works closely with the following cap liner providers. Feel free to review their information, and ask us how their products work with our induction cap sealing equipment.

SANCAP Liner Technology http://www.sancapliner.com

Selig Sealing Products, Inc. http://www.seligsealing.com/

Tech-Seal® http://www.tech-seal.com/products/index.htm#HIMI

Tri-Seal http://tri-seal.com/

Unipac http://www.unipac.ca/fi_index.html

Innerseal Materials

Innerseals are available in many variations to meet nearly any standard or customized packaging need. Modifications to suit the type of container, closure and product are available. There is virtually no limit to the size of container they will seal.

Innerseals consist of specially treated aluminum foil bonded to various types of proprietary films for use with virtually any type of container or closure, including HDPE, PE, PET, PETE, PETG, PVC, PP, BARREX, BARRIER, STYRENE and most thermoplastic containers as well as glass. They will provide tamper-evident hermetic seals suitable for use with foods, drugs, beverages, alkalies, acids, oils, organic solvents, flammables, powders, pellets and many other products. They are particularly effective for products that must be kept free from contamination, oxidation and moisture.

Lepel’s innerseals meet the stringent requirements set by the Food and Drug Administration.

Lepel’s innerseals meet the stringent requirements set by the Food and

Drug Administration.

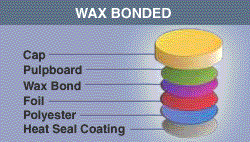

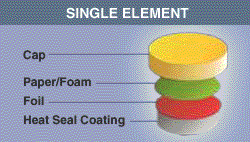

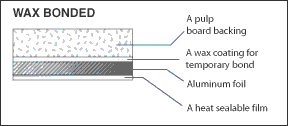

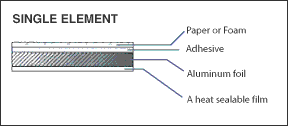

Innerseal Cross-Section

The induction liner is normally supplied to the closure manufacturer in coil strip form, similar to conventional lining materials. The foil innerseal is then die-cut and inserted into the closure with a die-cutting system by the closure manufacturer. Although available in a variety of forms, the innerseal is supplied in two basic structures, wax-bonded and single element. Each type has three basic parts:

- an aluminum foil layer, generally 0.001″ thick

- a heat sealable polymer film laminated to the foil, 0.001″ — 0.002″ thick

- a backing material of either paper, pulp or foam bonded to the foil either permanently with adhesives or temporarily with wax varying from 0.006″ — 0.035″ thick.